Twin ribs roofing machine can make two pathway design

usually we use hydraulic motor power to cut, this machine is electric motor power to cut

machine summary

siemens PLC and screen, yaskawa converter .

main motor power 7.5kw

electric cut power4kw

20 roller stations.

75mm diameter solid shaft.

suitable for one 40 GP loading.

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 8000kgs |

| Size | About 11m x 1.7m x 1.5m (length x width x height) |

| Color | Main color: green |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | PPGI and PPGL Coils |

| Thickness | 0.3-0.7mm |

| Coil width | 1250mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 20 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 7.5kw |

| electric motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

How to set up profile sheet roll forming equipment

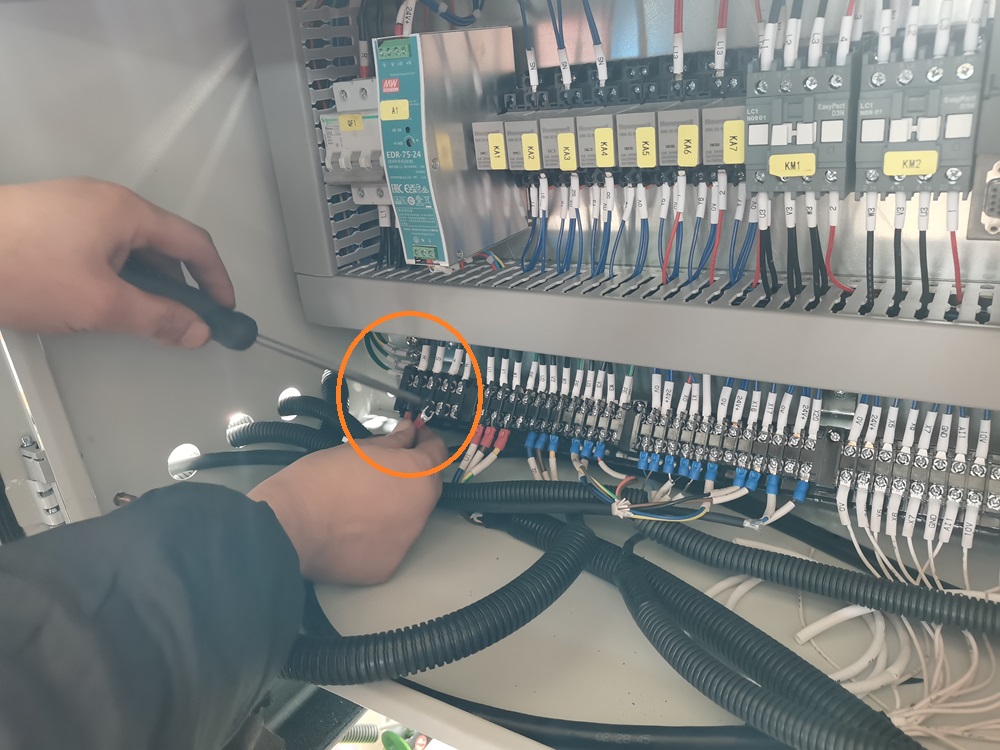

machine is well installed and connected, you only connect local wires

how to operate on PLC controller?

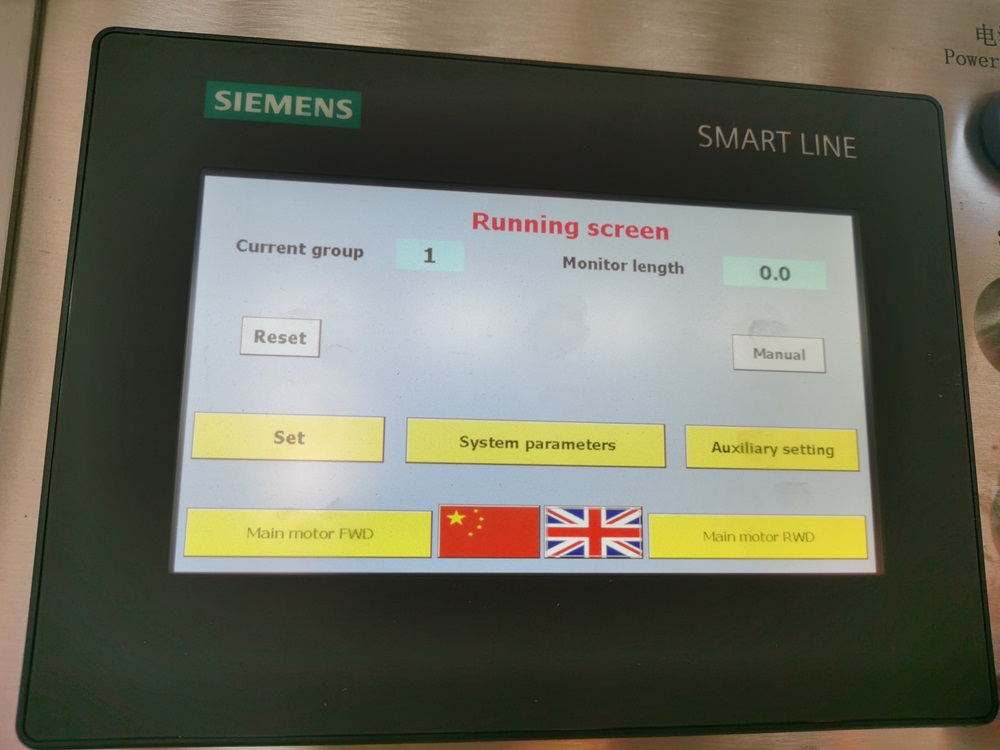

we use siemens touch screen with chinese and english language, your language can be set in if your required, such as spanish , russia

Here is main screen, on this screen, you can loose language.

choose machine manual work or automatical work.

you can make machine move forward or reverse on manual state.

you can monitor machine production, for example, what group is manufacturing, what length is manufacturing now.

you can also set length and piece for automatically work

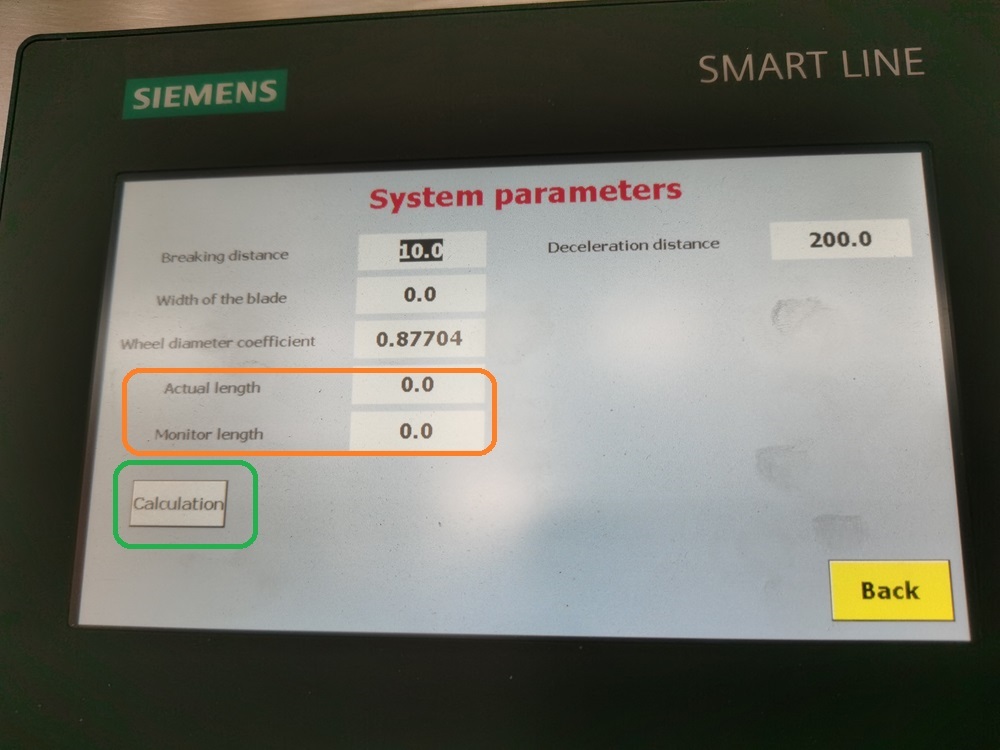

If sheets length is different with you set length , you just put in both length and press calculation, machine will make correction itself.