good quality C & U profile roll former,C & G profile forming machine,C & G purlin forming machine, This purlin machine make fixed size, here is 100mm size. if feed wider material , machine make C purlin with two lips, if feeding less width material, machine make U purlin without two lips. Therefore, no need to change rollers on forming machines.

On this purlin forming line, there are 3 punch devices for punching holes for screw. You could put in each purlin length and punch hole positions, machine will automatically work.

This purlin machine made for Australia customers, they pay great importance on safty, therefore , forming machines are fulled covered by safty net. in some cases, infrared sensor adopted for safty reason.

if you have large production requirement for fixed size, we suggest you this machines.

if you want to make different sizes of purlins, we suggest you this purlin machines:

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 5500kgs |

| Size | About 8m x 1.6m x 1.5m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 1.5mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | about 16 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | GR15 with quench treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: about7.5kw |

| Hydraulic unit motor power: about 11kw | |

| Electric voltage | According to customer’s requirement |

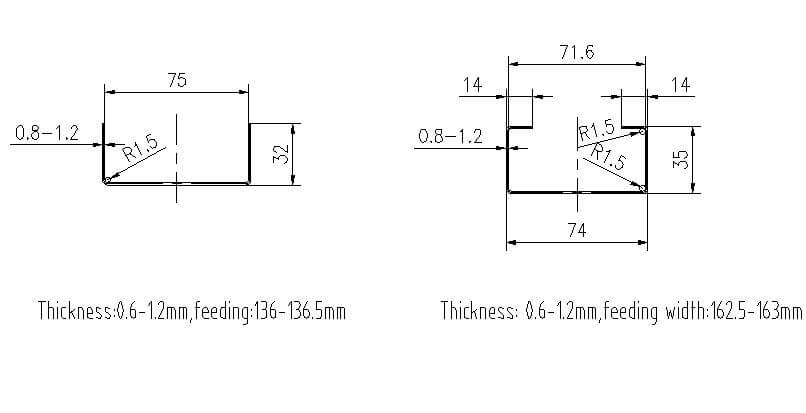

One machine can make C and G by feeding different width raw material,

No relate news.