Roofing ridge forming machine to make ridge cap suitable for steel roofing sheet top.Your ridge can be designed here.

here are some popular ridge machines for your reference, stop to cut machine, working speed about 12-15m/min, non stop to cut machine, working speed about 20m/min.

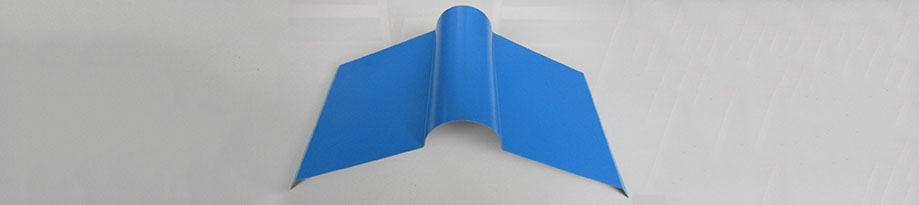

standard ridge with flat leg, which need to cut the leg according to roofing trapezoidal sheets during installing/

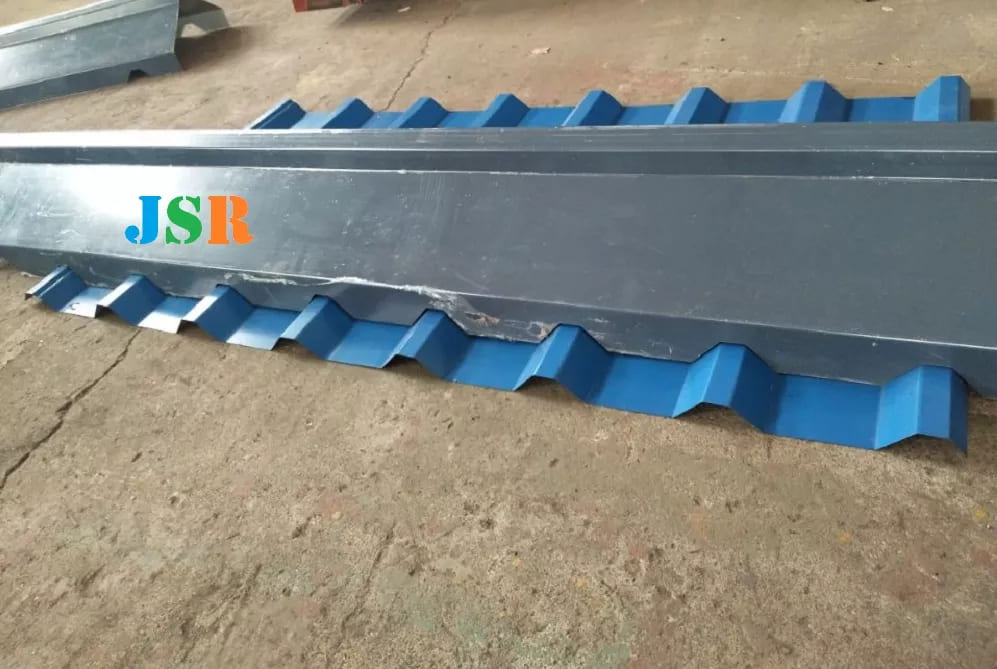

special ridge cutted according to roofing trapezoidal sheets, which can easily attached on roofing without futher cut during installing, which improve work efficiency greatly, and make great match to roofing sheets to water proof.

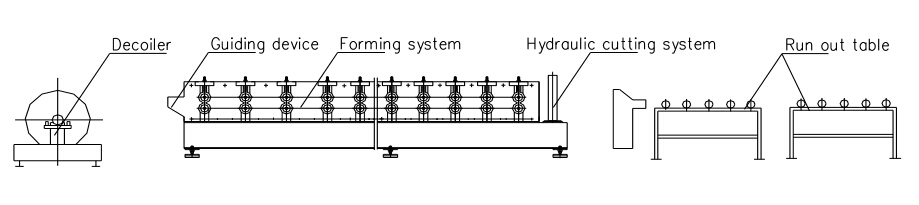

JSR ridge cap forming machines include 3 ton manual decoiler, forming machine with post cut, PLC controller , hydraulic station, PLC controller ,run out table

mitsubishi or siemens control system allow you user friendly, you only put in the length and pieces , roll forming machine will automatically work.

Besides, forming machines require little maintanance, you may lubricate the cut frame some times during daily productions.

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 4000kgs |

| Size | About 6m x 1.0m x 1.5m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | PPGI and PPGL Coils |

| Thickness | 0.3-0.8mm |

| Coil width | 610mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 55mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 4kw |

| Hydraulic unit motor power: 2.2kw | |

| Electric voltage | According to customer’s requirement |

JSR Machinery factory will design roofing machines according to your roofing profile or design, and Pre-engineered metal building advantages:

1 durable

2 withstand servere conditions.

3 low cost

4 low initial investment and low maintain cost

5 environment friendly

6 all the material can be recycled

7 flexible design

8 can relocate

9 install time considerably reduced

Operate easily , work automatically with PLC controller control.

Decoiler- forming-cut – run out

No relate news.