Australia Trimdek Sheet Roll Forming Machine – Lysaght Trimdek Sheet Roll Forming Machines with Australia safty standard in China.

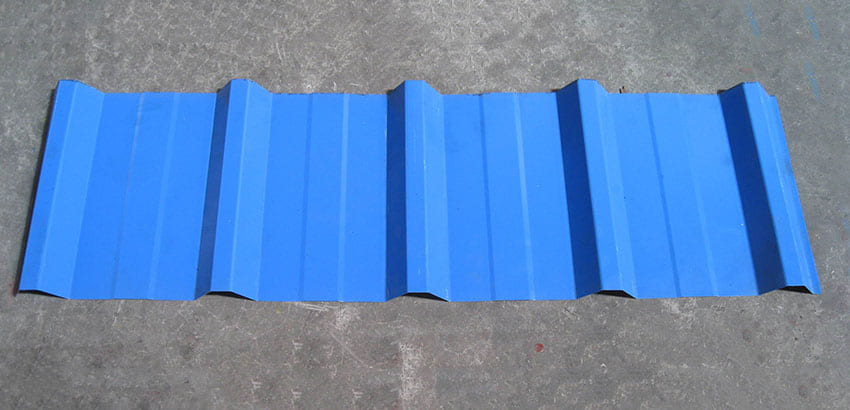

Trimdek roofing profile is a long spanning cladding permitting wide support spacing & is a versatile, strong yet lightweight profile.

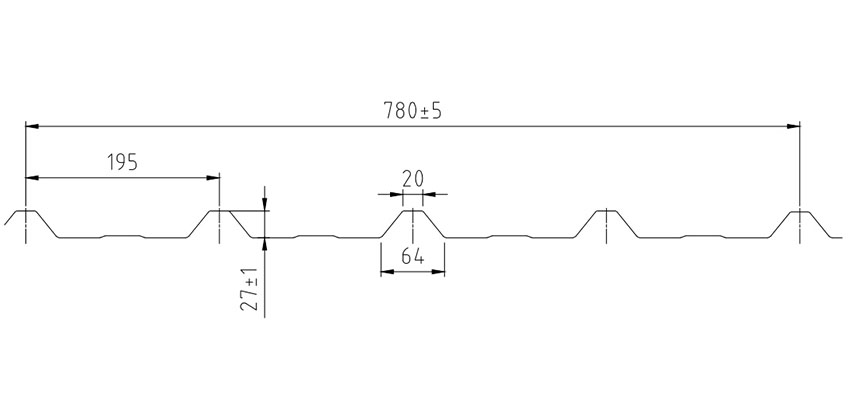

Trimdek’s 760mm sheet coverage is economical and quick to install. The 28mm rib height and specially designed capillary groove ensures watertightness down to a two degree roof pitch.

What is the sheet cover?

Cover width is 762mm. The actual sheet width is 820mm.

What is the steel thickness?

.42 -0.48BMT is the standard thickness of BlueScope Lysaght Steel sheets.

besides, australia popular profiles are

corrugated roofing

kliplop 700

spandek

Australia usually use hard material, yield strength 500mpa to increase hardness of final roofings.

hard material are easy to break during forming, because hard material is brittle.

we , JSR machinery factory have many years experience to design and manufacture such roll forming machines

gutter machines, facsia machines, c purlin machines already made to Australia.

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 7500kgs |

| Size | About 10m x 1.7m x 1.5m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Colored Steel Coils |

| Thickness | 0.3-0.7mm |

| Coil width | 960mm |

| Yield Strength | 550Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 20-22 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 7.5kw |

| Hydraulic unit motor power: 3kw | |

| Electric voltage | According to customer’s requirement |

JSR Machinery factory will design roofing machines according to your roofing profile or design, and Pre-engineered metal building advantages:

1 durable

2 withstand servere conditions.

3 low cost

4 low initial investment and low maintain cost

5 environment friendly

6 all the material can be recycled

7 flexible design

8 can relocate

9 install time considerably reduced

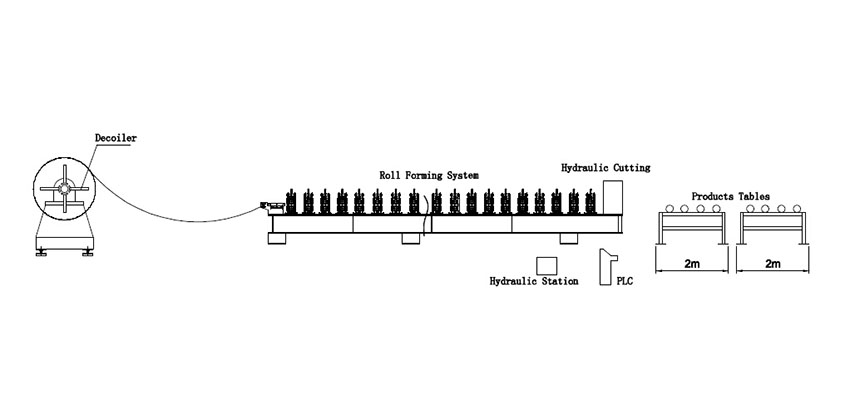

Operate easily , work automatically with PLC controller control.

Decoiler- forming-cut – run out

roll forming machine working video in customer factory

cladding profile making machine in India

Mini orb profile forming machine in Malaysia

IBR roll forming line in Malawi

trapezoidal roll former in Colombia

fast speed roof panel forming machine in Bengal