JSR machinery factory has been manufacturing many different types of deck machines, such as roof deck machine, floor deck machine, dovetail deck machine.

Dovetail type deck allows for more sound absorbing concrete materials than other deck design. Besides, dovetail shaped deck with embossed ribs. It forms a very strong, permanent bond with the concrete poured onto it, and acts as reinforcement for the slab.

For dovetail deck machine, we use more stronger structures, solid 95mm diamter shaft, while usual deck machine with85mm diameter; more power motor, 3x11kw , while usual deck machine with 2x11kw.

Advantage of decking machine:

1. The steel decks are flat, high precision within 1mm, and the effective width is controlled within 5mm;

2. Adopt 85-95mm solid shaft and H-shaped steel as the underframe, so that the machine can withstand long-term production without deformation of the machine, thus ensuring long-term machine use life;

3. The rollers are processed by CNC machine tools to ensure the accuracy of the rollers, and thus the accuracy of the final deck.

4. Our cut blade frame is stress-relieved to ensure that it is not deformed during long-term production and makes the final product smooth.

5. Use Mitsubishi or Siemens operating system with stable performance, simple operation, as long as the input length and quantity are automatically produced by the machine, and the cutting length tolerance is within ± 2mm

6. Forming speed can reach 8-12 meters per minute

7. The machine weighs about 15-18 tons

Profile of steel deck:

deck 2”

deck 3”

deck 1.5”

deck 840

trd-91.5

dove tail

roof deck floor

floor deck

bridge deck

deep deck

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 15000kgs |

| Size | About 16m x 1.8m x 1.5m (length x width x height) |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 0.8-1.2mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 95mm |

| Roll Forming Speed | 10-15/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 3x11kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

Steel deck or floor deck are widely use nowadays, for following advantage:

1.Reduce steel frame weight

2.No need formwork for concreting

3.Install speed faster

4.Safe working platform for workers.

JSR machinery factory manufacture all kinds of steel deck forming machine, or floor decking machine machine.

Operate easily , work automatically with PLC controller control.

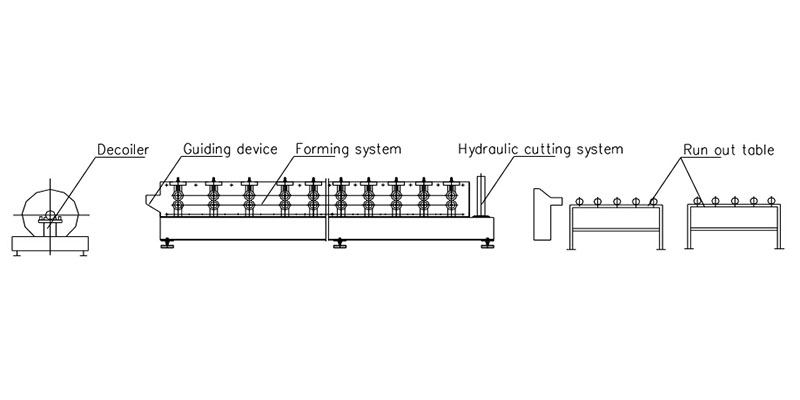

Decoiler- forming – cut – run out

deck machine working video in customer factory