JSR manufacture most popular type and size of slotted struct channel roll forming

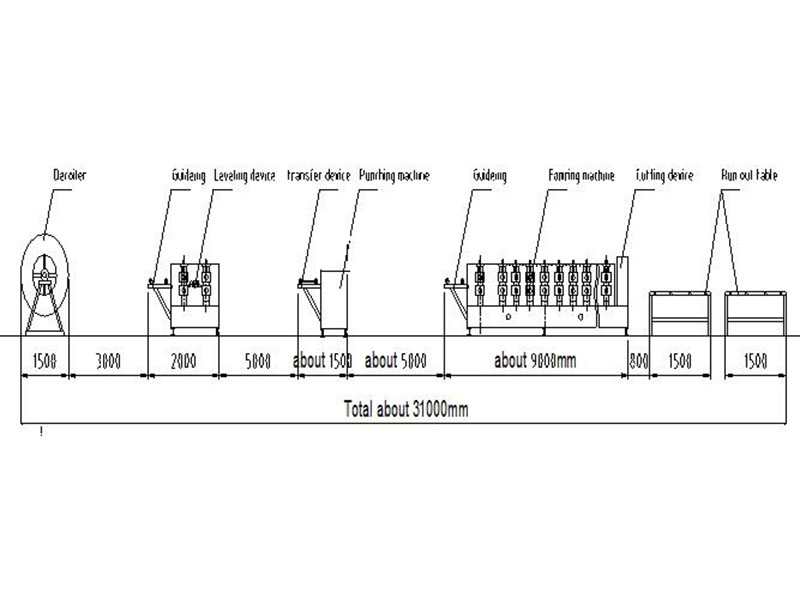

unistrut channel forming machine process:

decoiler the coil- leveling- servo feeding- punch -forming – cut- run out table

Main features of c struct channel forming machine:

suitable for material1.2-2.5mm

roller material Gcr15 mould steel

gear and chain move the line or gearbox move the line are optional

this strut channel with perfect curved edges, used to support solar panel to collect sun energe for electricity.

uni strut channels provide ideal framework for support system without the need for welding, full flexibility and easy install.

this c strut profile line with HYDRAULIC PUNCH, working speed about 4m/min

and this c profile roll former with punch machine, working speed about 8m/min, if you make loop in the floor , speed faster

above two machines, punch hole before forming, while this line only form and cut c strut channel shape, workers takes to punch manually. machine working speed about10m/min

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 10000kgs |

| Size | About 20m x 1.0m x 1.0m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized steel |

| Thickness | 1.5-2mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 22 |

| Diameter of forming rollers shafts | 60mm |

| Working Speed | 4m/min |

| Forming rollers material | Gr15 mould steel, with quenched treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: about 22 kw |

| Hydraulic station | Motor 15.5kw |