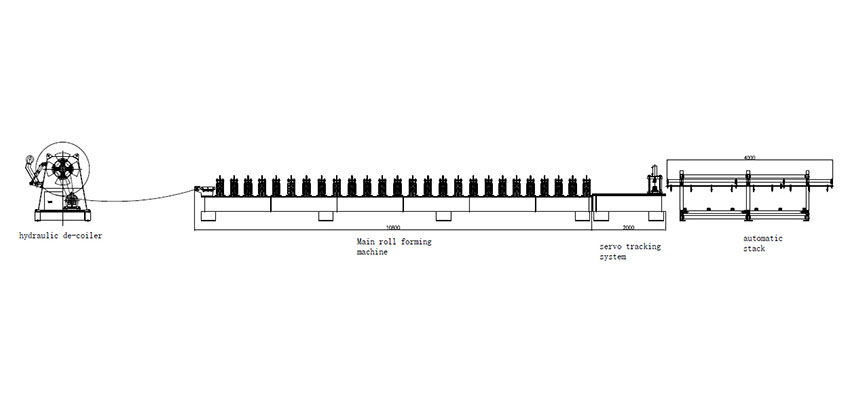

Full automatical panel forming line adopt non stop cut servo system, which increase forming machines working speed. JSR machinery factory can make rollforming machine speed from 25m/min to 60m/min.

roofing panel forming machine include 5 or 10 ton hydraulic decoiler and loading car, forming machine with post cut, 6m or 12 m automatical stacker, siemens or mitsubishi plc controller, hydraulic station.

process: decoiler material- forming – cut- sheets to stacker

according to profile design, raw material and speed requirement, we will choose chain and gear move the line or gearbox move the line.

This full automatical machine, one worker can operate one or more roll forming machines.

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 15000kgs |

| Size | About 12m x 1.7m x 1.5m (length x width x height) |

| Color | Main color: Green |

| Warning color: yellow | |

| Suitable Raw Material | |

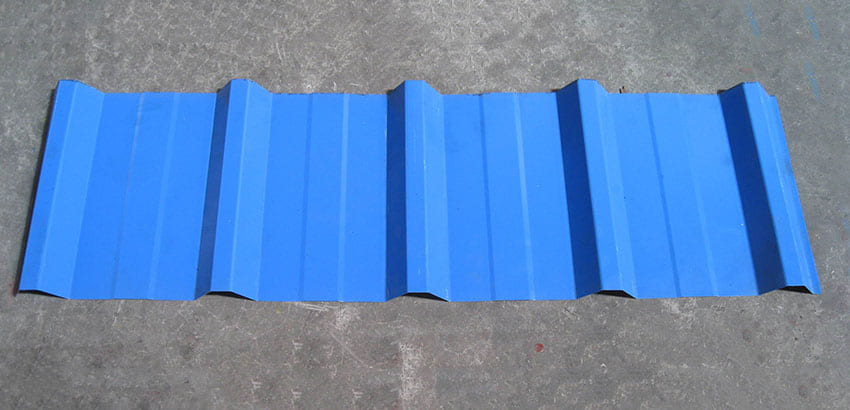

| Material | PPGI and PPGL Coils |

| Thickness | 0.3-0.7mm |

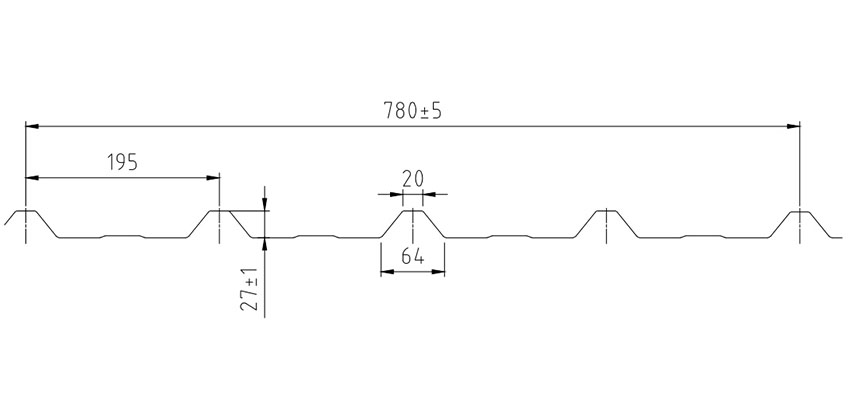

| Coil width | 1220mm |

| Yield Strength | 235Mpa-550Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 22-24 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | up to 60m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Cutting type | Non-stop cutting design (fly cutting) |

| Electric Power requirement | Main motor: 11kw |

| Servo motor: 2.2kw | |

| Hydraulic unit motor: 5.5kw | |

| Electric voltage | According to customer’s requirement |

JSR Machinery factory will design roofing machines according to your roofing profile or design, and Pre-engineered metal building advantages:

1 durable

2 withstand servere conditions.

3 low cost

4 low initial investment and low maintain cost

5 environment friendly

6 all the material can be recycled

7 flexible design

8 can relocate

9 install time considerably reduced

Operate easily , work automatically with PLC controller control.

Decoiler- forming-cut – run out

No relate news.