Stud & Track Roll Forming Machine, if feed wider material, forming machine make stud, if feed less width material , machine make track, you can also program to punch on stud or track.

stud and track and omega channel are called as drywall channels,they are used to make economic wall and ceiling frame .

Metal studs and channels are strong, light weight, easy to install and come in a range of sizes to provide ideal wall and ceiling applications with multiple layers of gypsum board.

drywall forming machine automatically work with mitsubishi or siemens control syestem

This is furring channel forming machine working in customers’ factory

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 3500kgs |

| Size | About 6m x 1.6m x 1.5m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 0.3-0.6mm |

| Coil width | 153mm and 175mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 12-14 |

| Diameter of forming rollers shafts | 60mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5.5kw |

| Hydraulic unit motor power: 3kw | |

| Electric voltage | According to customer’s requirement |

JSR Machinery factory will design drywall (stud and track) forming machines according to customers ‘ requirement.

If stud and track width same, stud and track can be made from the same machine, just feeding in different width for stud and track.

If stud and track width difference small, for example, 1mm or 2mm, we will design another three stations rollers as a whole set to replace, therefore, the same machine can make stud and track.

If your production is big, we suggest you buy two machines, one machine for stud and one machine for track, two machines work together.

Operate easily , work automatically with PLC controller control.

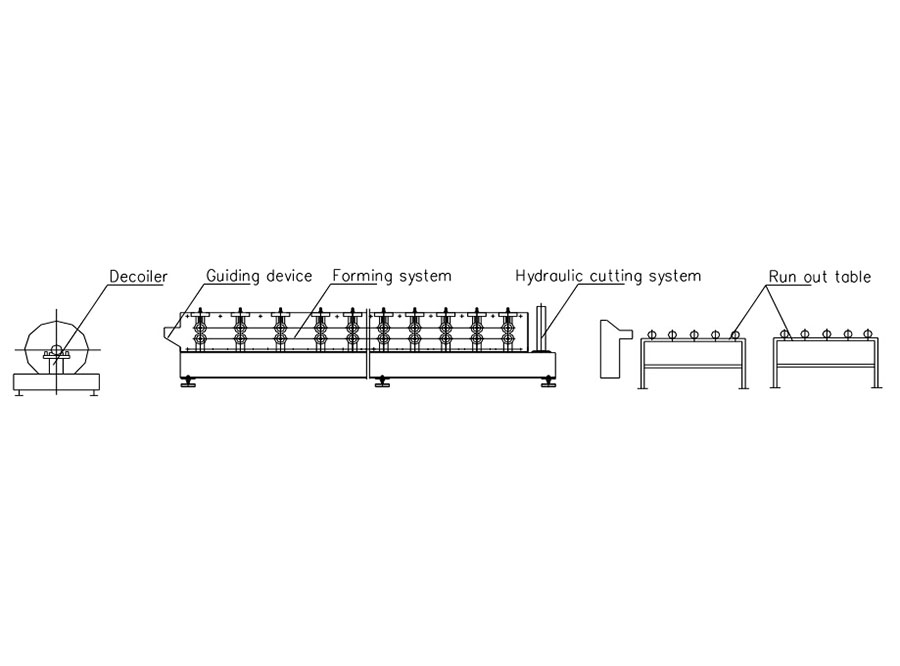

Decoiler- forming-cut – run out

how to set up steel stud & track wall frame roll forming machine

roll forming machine is well installed and tested before delivery, when machine arrive in customer factory, customer only connect some wires and tubes according to video, you will find set up is easy, most customer can DIY.

No relate news.