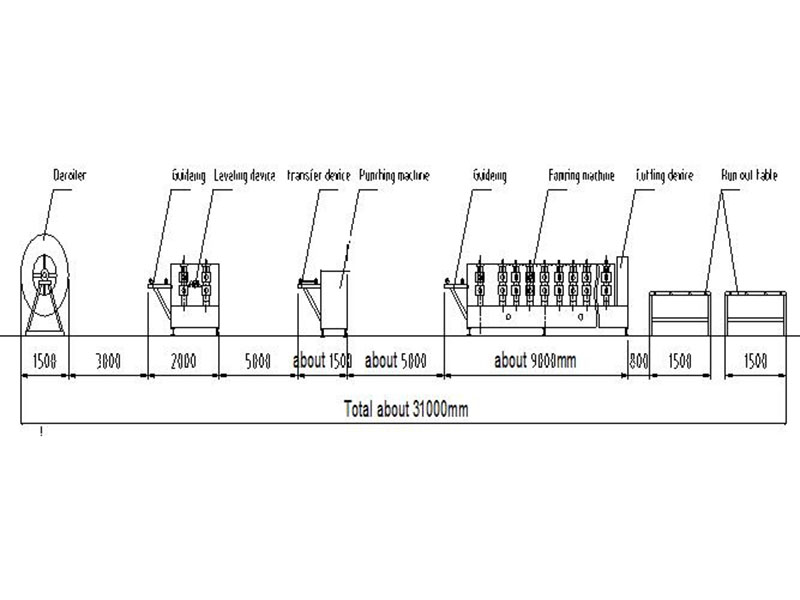

Rittal C Profile Rail Forming Machine to make profile c by process: decoil material-leveling-punch-forming-cut

this forming machine adopt one whole piece steel plate as structure to hold roll stations , steel plate thickness 25mm,advantage is more precise for forming machines.

Main features of rittal c profile rail forming machine

main motor about11kw

roller material Gcr15

mitsubishi or siemens control system

Application of c rails

For direct external mounting between the vertical TS, SE enclosure sections. The angle bracket, C-section, is additionally required for mounting between the horizontal TS, SE enclosure sections. Due to the universally designed attachment piece, the C rails may optionally be attached to the inner or outer level of the TS 8 frame.

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 8000kgs |

| Size | About 10m x 1.0m x 1.0m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized steel |

| Thickness | 2mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 20 |

| Diameter of forming rollers shafts | 60mm |

| Working Speed | 4m/min |

| Forming rollers material | Gr15 mould steel, with quenched treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5.5×2 kw |

| Hydraulic station | Motor 3kw |

Wuxi Jingshirui Machinery Factory, (JSR) manufacture all kinds of roll forming lines, such as,

Roof &Wall Machine,

C/Z Purlin rolling Machines,

Floor Deck Machines,

Cable Tray form Machines,

Walk Board Scaffolding Planks Machines,

Guardrail Forming Machines,

Rack Machines and Step Beam forming Machines,

Dry Wall rolling machines,

and other machines designed to customers requirement.

No relate news.