How to set up Drip Edge Roll Forming Machines

you will get roll forming machine work immediate once you have machine in your factory.

your profile roll forming machine can be designed and quoted here,

your machine install video will be taken for you.

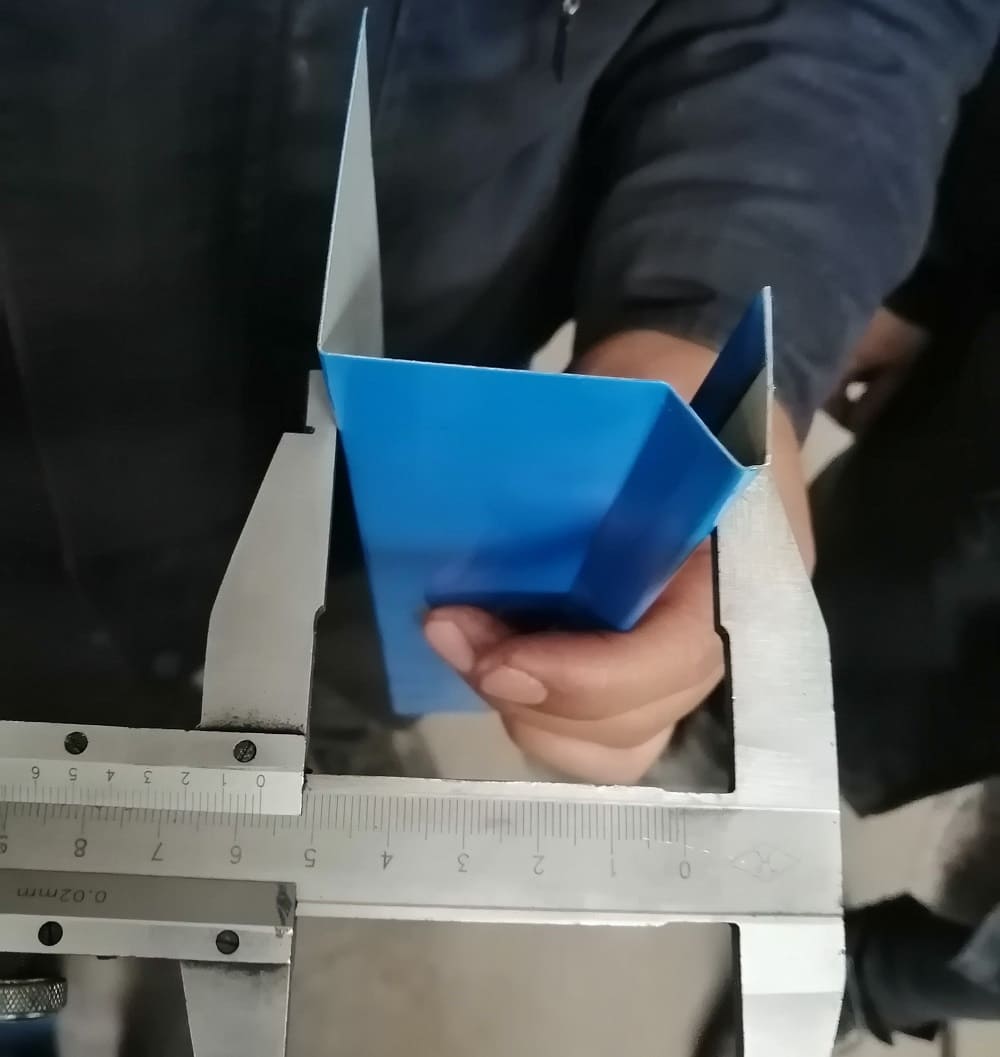

1 ) Suitable Coil Thickness: 0.4-0.48mm

2 ) Suitable Raw Materials: PPGI

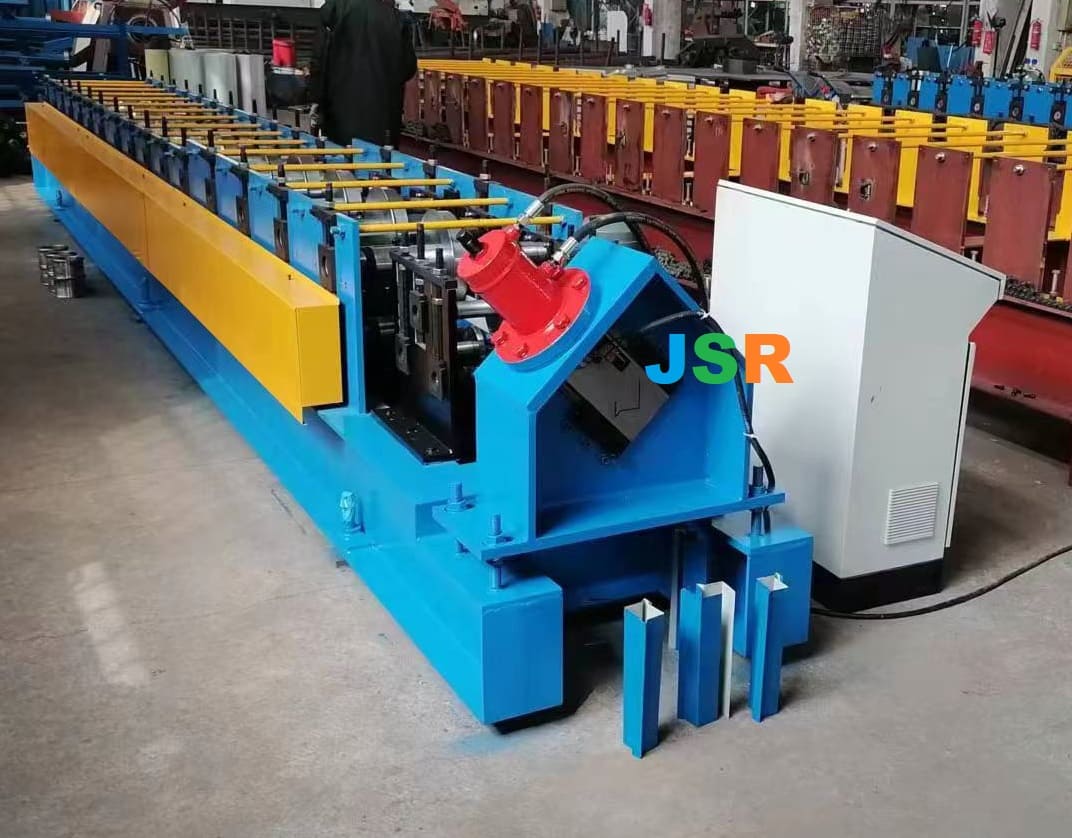

(1) Manual decoiler 1 set(Capacity : 3 tons)

(2) Roll-Forming M/C 1 set

(3) Hydraulic Cutting 1 set

(4) Hydraulic station 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set (two pieces, total length is 3 meters)

SPECIFICIATION

Main motor of drip edge machine, 4 kw.

hydraulic motor ofdrip edge trim machine, 3 kw

about 14 roller stations

siemens plc and screen, yasakawa converter

power voltage can de designed according to buyer’s requirement

TERMS

you maybe interested in our other machines,

such as fascia roll forming machine

gutter roll forming machine

downspout roll forming machine