Our technician visit our customer factory in vatuatu help set up roofing corrugated machine

machine works well , the following comments from customer for our machine working and technician service

His work so far has been excellent and my team very happy.

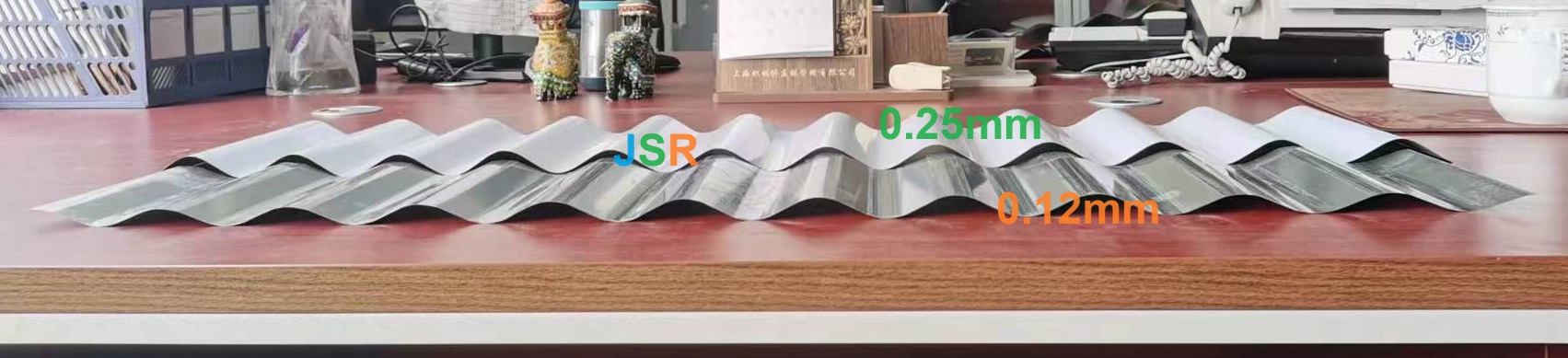

this corrugated profile sheet material only 0.12 mm thickness

you will see height difference if we make 0.12mm thickness raw material and 0.25mm thickness material

while raw material with different thickness and hardness, machine will be designed differently, cost differently.

usually, material thickness 0.3-0.7mm , width 1000mm or 1220mm,

or material thickess less than 0.3mm, specially rollers and more rollers required.

you will see from video the quality of corrugate sheet in thin material.

we, JSR machinery factory are experienced in making both thickness material machines,

our corrugate machines are already in Australia, Malawi,Angola, Colombia, Mexico, Argentina….

Suiting raw material for corrugate roll former

1 ) Coil Width: 1000mm

2 ) Suitable Coil Thickness: 0.12mm -0.25mm

3 ) Suitable Raw Materials: galvanized steel sheet

4) Yield strength of raw material: 235-345Mpa

Main parameters of corrugate panel roll forming machine

1) Forming Speed: Max. About 25m/min. (excluding the cutting time)

2) Main Motor Power: 7.5KW(Depend on final design)

3) Hydraulic Station Power: 3KW (Depend on final design)

4) Control System: Mitsubishi PLC and transducer (Japan)

5) Encoder: Nemicon (Japan)

6) Rollers’ material High grade No.45 forged steel, with digital-controlled procession,

plated with chrome on surface. 20 roller stations

7) Shaft diameter 75mm, tooled by grinding machine for two times

to ensure the precision of final product.

8) Type of Cutting: Length-set cutting and post forming style

9) Electric Condition: 440V/3Phase/60HZ(or depend on customer)

10) Total Weight: About 6500 Kg

Main components of corrugate roll forming machine

(1) Manual decoiler 1 set(Capacity : 7 tons)

(2) Roll-Forming M/C 1 set

(3) Hydraulic Cutting 1 set

(4) Hydraulic station 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set