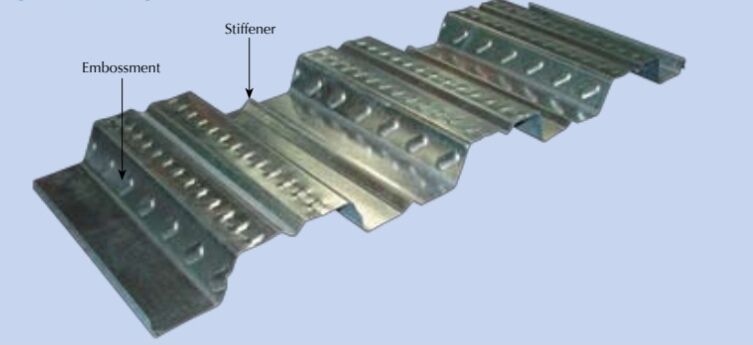

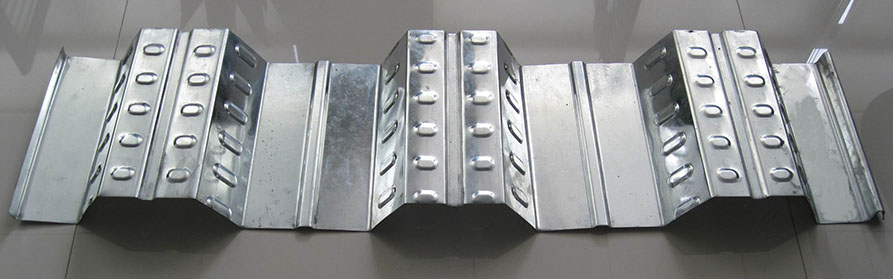

FLOOR DECKING designed for use with structural concrete and is manufactured with mechanical embossments in the webs to create mechanical bond between the deck and the concrete.

Advantage of deck forming machine:

1. Adopt 85-95mm solid shaft and H-shaped steel as the underframe, so that the machine can withstand long-term production without deformation of the machine, thus ensuring long-term machine use life;

2. The rollers are processed by CNC machine tools to ensure the accuracy of the rollers, and thus the accuracy of the final deck.

3. Our cut blade frame is stress-relieved to ensure that it is not deformed during long-term production and makes the final product smooth.

4. The steel decks are flat, high precision within 1mm, and the effective width is controlled within 5mm;

5. Use Mitsubishi or Siemens operating system with stable performance, simple operation, as long as the input length and quantity are automatically produced by the machine, and the cutting length tolerance is within ± 2mm

6. Forming speed can reach 8-12 meters per minute

7. The machine weighs about 15-18 tons

Profile of floor deck:

deck 2”

deck 3”

deck 1.5”

deck 840

trd-91.5

Conponents of floor deck forming machines

7 ton manual decoiler, forming machine with post cut, plc controller, hydraulic station,run out table

if you need full automatical deck machine, equipped with hydraulic decoiler and automatical stacker with extra cost

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 15000kgs |

| Size | About 16m x 1.8m x 1.5m (length x width x height) |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 0.8-1.2mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 85mm |

| Roll Forming Speed | 10-15/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 2x11kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

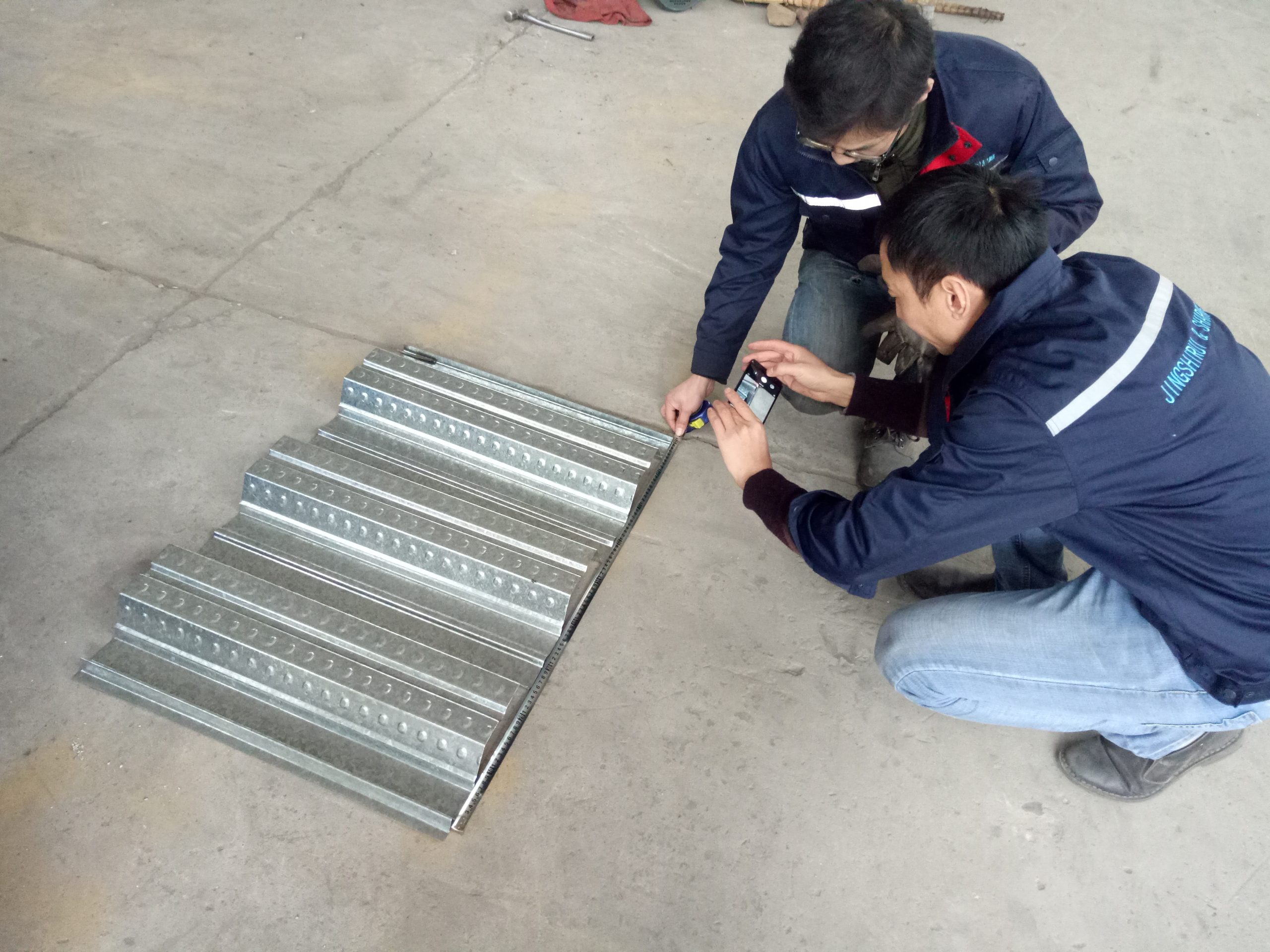

deck dimension quality, such as cover width , flatness.straightness and consistent emboss depth garantee the decks can erect efficiently in the field.

Steel deck or floor deck are widely use nowadays, for following advantage:

Light weight : Concrete floor weight reduces by almost 50%.

Economical : Doesn’t require additional support, reduces use of concrete, reduces slab thickness, savings in reinforcement steel.

Time Saving : Easy nd rapid intallations to major reinforcement required

Multiprupose : Widely used in multistory buildings, malls, markets, storage facilities mezzanines, bridges, walkways, platforms, warehouses, industrial sheds, control rooms.

Aesthetics : Offer internal polished look available in variesty of colors. So no need to internal plastering of roof

JSR machinery factory manufacture all kinds of steel deck forming machine, or floor decking machine machine.

Operate easily , work automatically with PLC controller control.

Decoiler- forming – cut – run out

deck machine working video in customer factory

how to set up roll forming machine