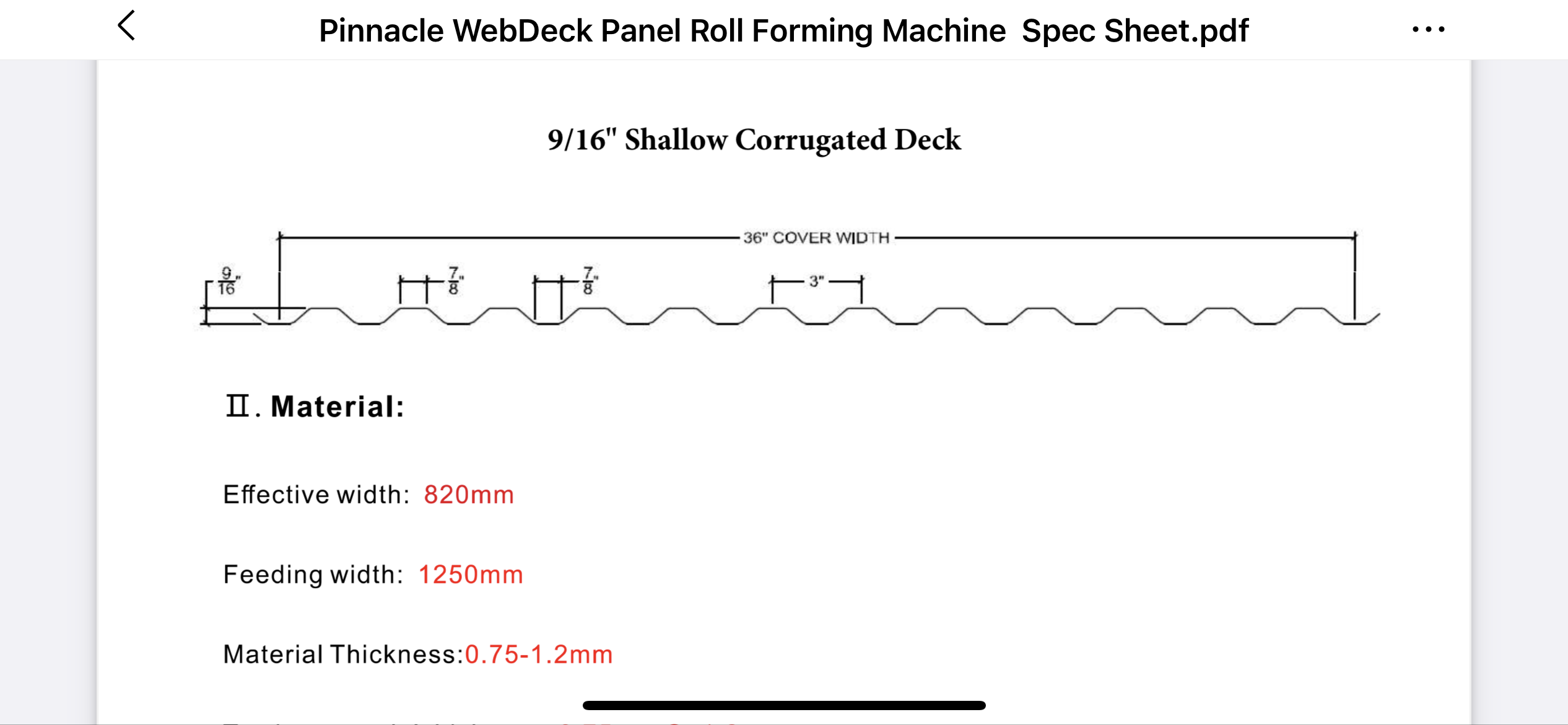

9/16” form deck is used extensively in floor construction as an economical form to support concrete slabs during construction. This metal form deck is used to serve as a permanent steel base for poured concrete. The advantage to using a form deck is that it eliminates the time and cost of wood forming making it a quick, easy, and affordable solution.

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 15000kgs |

| Size | About 16m x 1.8m x 1.5m (length x width x height) |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 0.8-1.2mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 90mm |

| Roll Forming Speed | 10-15/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 2x11kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

Steel deck or floor deck are widely use nowadays, for following advantage:

1.Reduce steel frame weight

2.No need formwork for concreting

3.Install speed faster

4.Safe working platform for workers.

JSR machinery factory manufacture all kinds of steel deck forming machine, or floor decking machine machine.

Operate easily , work automatically with PLC controller control.

Decoiler- forming – cut – run out

deck machine working video in customer factory