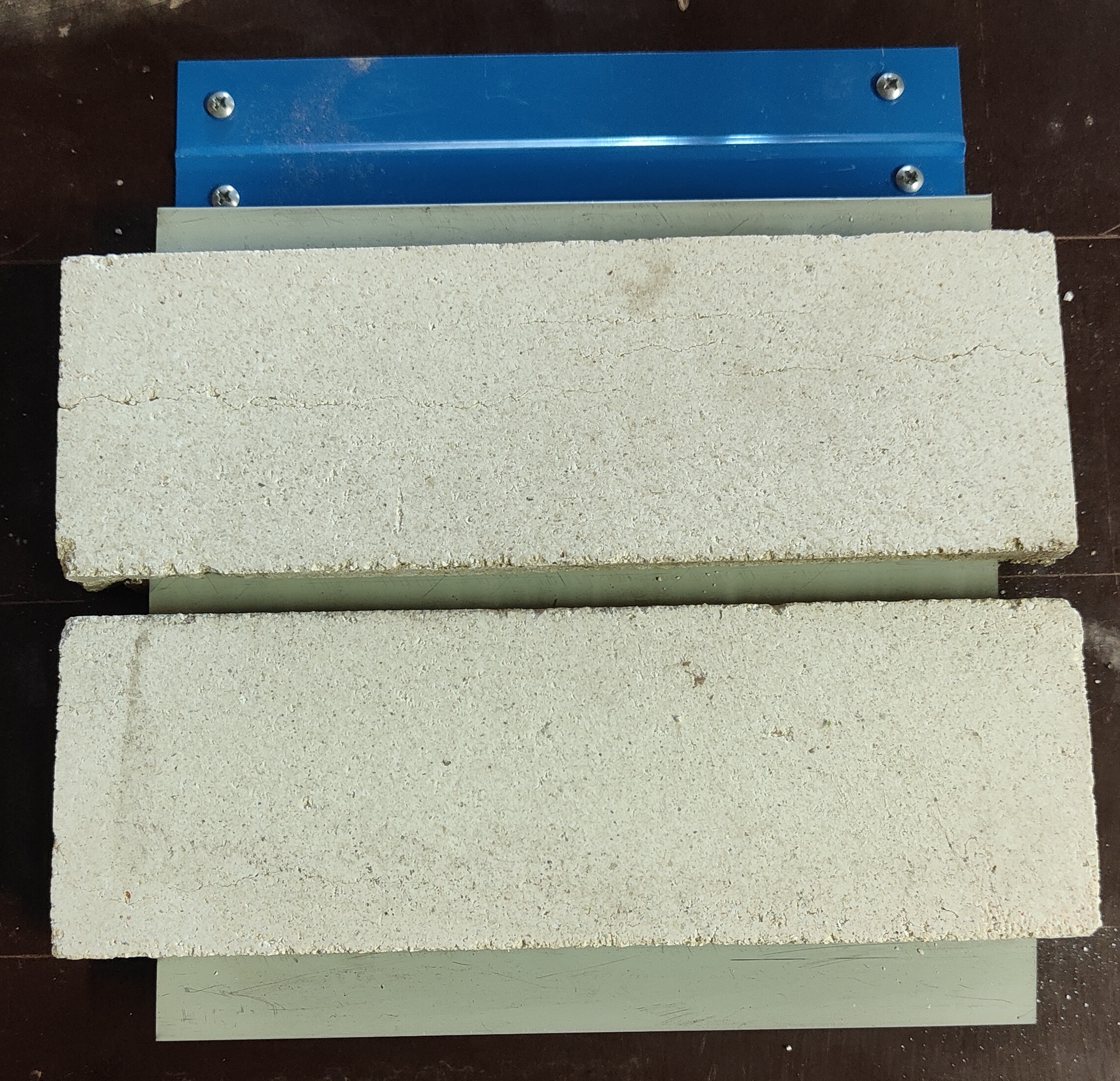

the rails support brick slices for thin brick walls.

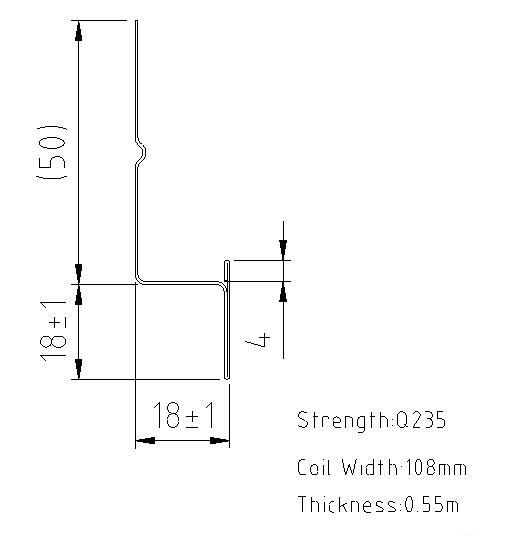

1 ) Suitable Coil Thickness: 0.55mm

2 ) Suitable Raw Materials: GALVALUME COILS

3) Yield strength of raw material: 235-345Mpa

(1) Manual decoiler 1 set(Capacity : 3 tons)

(2) Roll-Forming M/C 1 set

(3) Hydraulic Cutting 1 set

(4) Hydraulic station 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set (two pieces, total length is 3 meters)

Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.