Roll forming machine can equipped with manual decoiler

Manual decoiler need worker use crame or forklift to take core off, insert core to coil and locked, use crame and forklift to put on stand base.

if roll forming machine with hydraulic decoiler, worker only put coil on loading car, then press bottom to load coil onto hydraulic decoiler, whats’more, hydraulic decoiler has power to move forward and reverse, the most inportant is , there is sensor, which will monitor decoiler speed.

Therefore, hydraulic decoiler can improve roll forming machine degree of automation and efficiency.

and automatical stacker also available

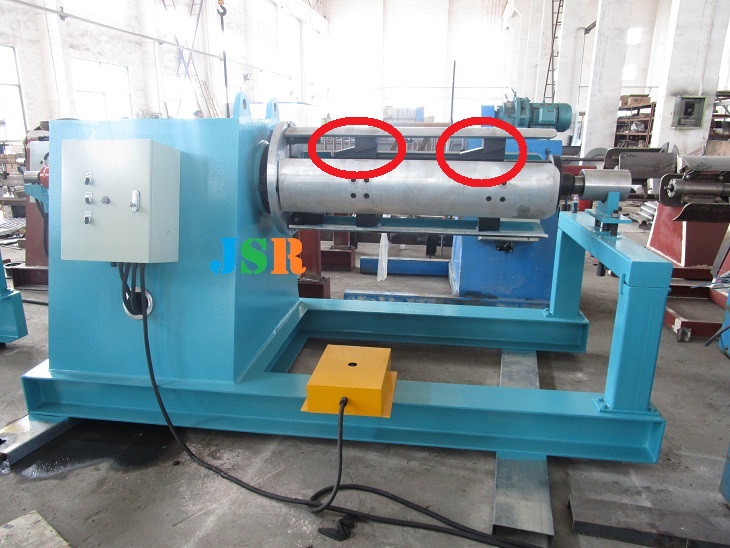

Here is 10 ton hydraulic decoiler with loading car

Max loading capacity 10T

Suitable coil ID φ410-550mm

Suitable material width (max.) 1250mm

Suitable coil OD (max.) φ1300mm

Motor power 5.5Kw

Hydraulic station 5.5kw

Electric condition 415V/3Phase/ 50HZ (please confirm with us )

Decoiling type motor driving

Expand and shrink hydraulic

Speed control infrared sensor

Size(length x width x height ) about 3.5x2x2m

while 5 ton capicity or hydraulic decoiler without loading car are also available

advantage of our hydraulic decoiler

expand bar design is very strong