Suiting raw material for corrugate roll former

1 ) Coil Width: 940mm

2 ) Suitable Coil Thickness: 0.4mm -0.5mm

3 ) Suitable Raw Materials: galvanized steel sheet

4) Yield strength of raw material: 550Mpa

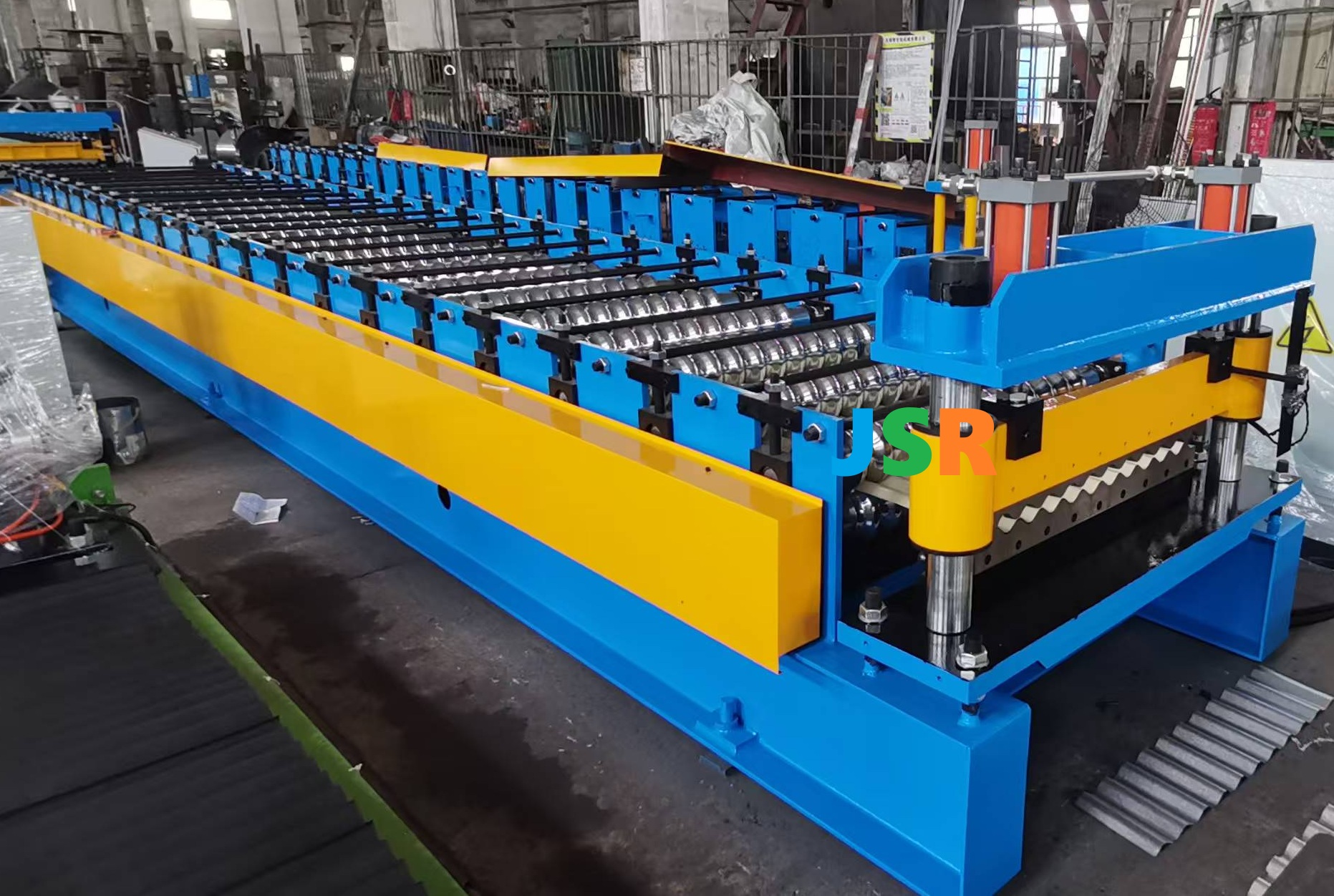

Main parameters of corrugate panel roll forming machine

1) Forming Speed: Max. About 25m/min. (excluding the cutting time)

2) Main Motor Power: 7.5KW(Depend on final design)

3) Hydraulic Station Power: 3KW (Depend on final design)

4) Control System: Mitsubishi PLC and transducer (Japan)

5) Encoder: Nemicon (Japan)

6) Rollers’ material High grade No.45 forged steel, with digital-controlled procession,

plated with chrome on surface. 21 roller stations

7) Shaft diameter 75mm, tooled by grinding machine for two times

to ensure the precision of final product.

8) Type of Cutting: Length-set cutting and post forming style

9) Electric Condition: 380V/3Phase/50HZ(or depend on customer)

10) Total Weight: About 7500 Kg

Main components of corrugate roll forming machine

(1) Manual decoiler 1 set(Capacity : 5tons)

(2) Roll-Forming M/C 1 set

(3) Hydraulic Cutting 1 set

(4) Hydraulic station 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set