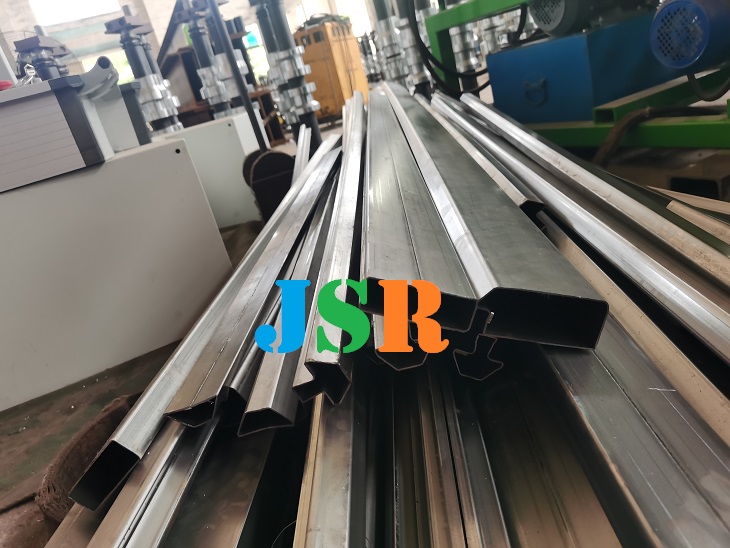

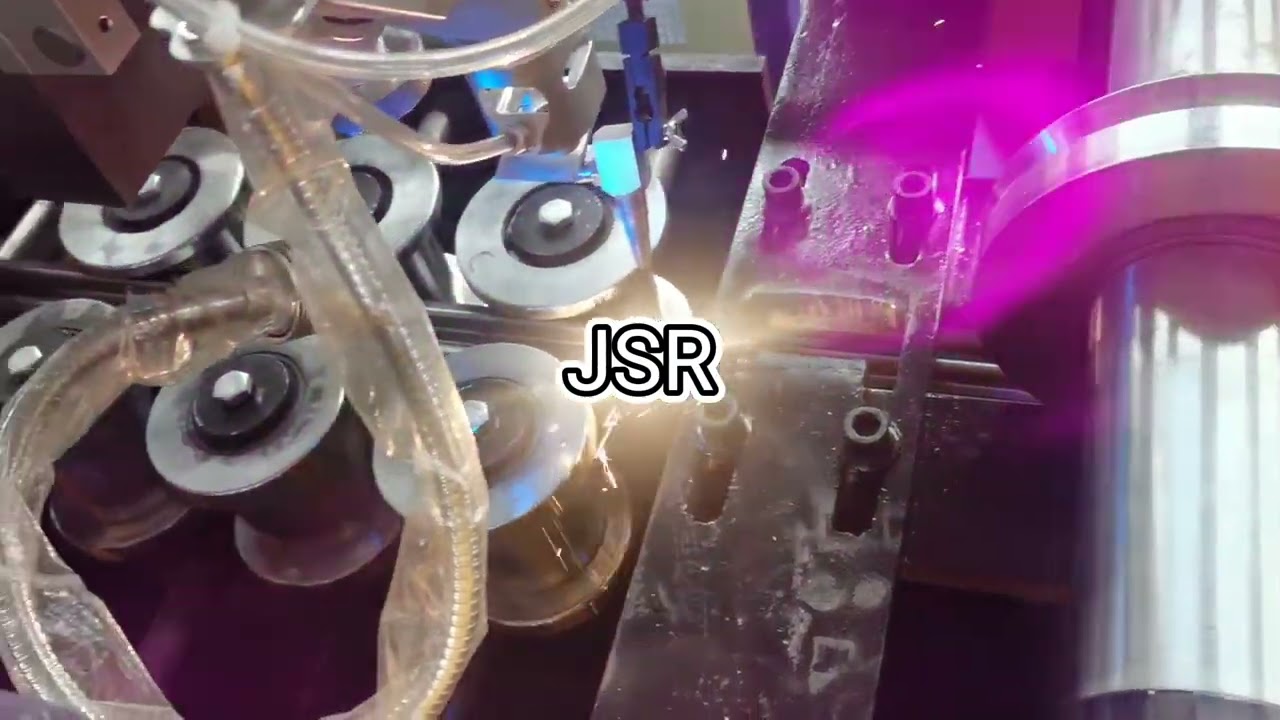

cassette structure roll forming machine for 4 support profile or custom profiles.

the above video show you how to change cassette unit, it is easy and time saving.

4 profile roll former share one same base, main motor 7.5kw, control system and 3000w laser welding .

for raw material thickness 1.2mm, working speed about 6-10m/min

window support profile machine

trapezoidal perfil roll forming machine

rectangular pipe square tubing steel profile machine

beam roll forming machine

JSR make machine with great precision and shape.

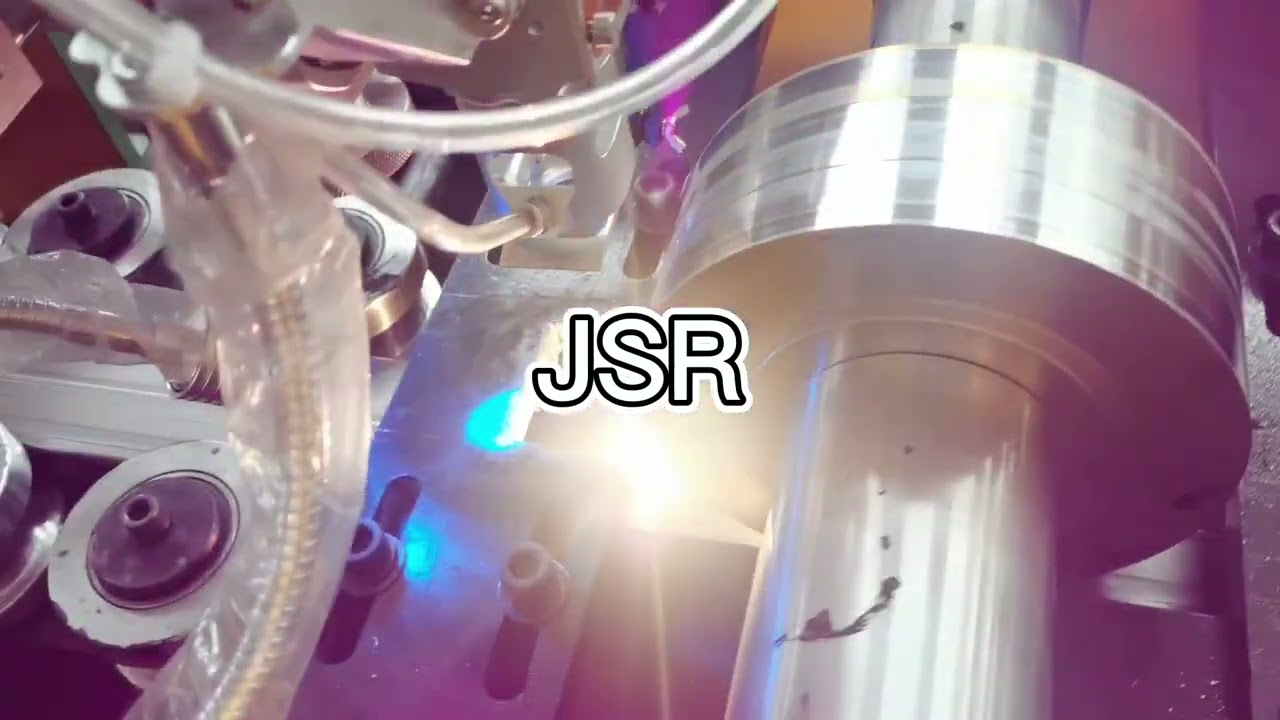

machine adopt laser welding system. test welding part by heavy hammer

control system: yaskawa converter, siemens PLC and screen, omoron encoder,

big and strong brand to garantee stable use of machine for long time.

Technical Details

| The Line’s Specifications | |

|---|---|

| Weight | About 7000kgs |

| Whole line’s dimension | About 12m x 2m x 1.6m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 1-1.5mm |

| Coil width | 238mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 20 |

| Diameter of forming rollers shafts | 82mm |

| Roll Forming Speed | 8-10m/min |

| Production Speed | about6m/min |

| Forming rollers material | GCR15mould steel, with quenched treatment |

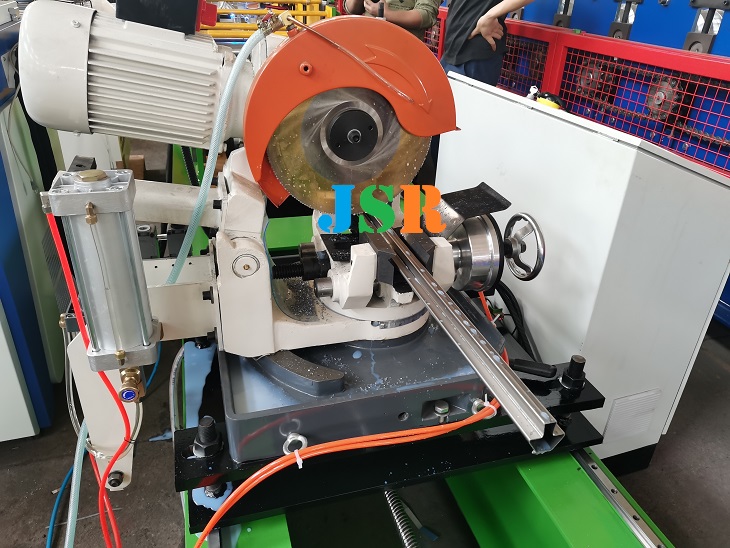

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: about7.5kw |

| Electric voltage | According to customer’s requirement |

| Main Components | |

| Decoiler (manual and automatic for options) | 1 set |

| Guiding device | 1 set |

| Leveling system | 1 set |

| Roll Forming system | 1 set |

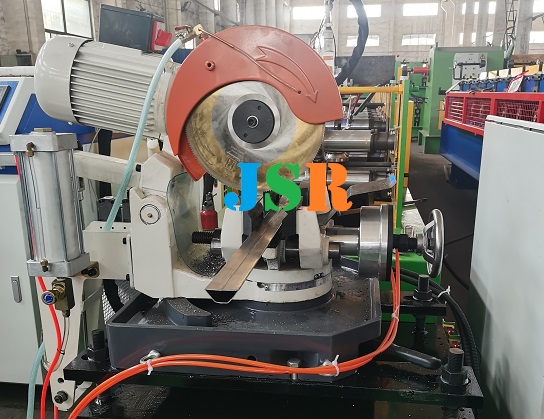

| Sawing system | 1 set |

| PLC control box | 1 set |

| laser welding device | 1 set |

| Run outs tables | 1 set |

No relate news.