machine to make adjustable Knocked Down Door Frame, they are easy to install and durable.

You will see in the video, machine will paint logo on metal door frame.

for this door frame forming machine working speed about 4m/min,

process: decoiler material- leveling- hydraulic punch and cutting-forming

installation space about 35-40m

most important. the width and length of door frame can be adjusted on machine.

that is you can make different width steel door frame .

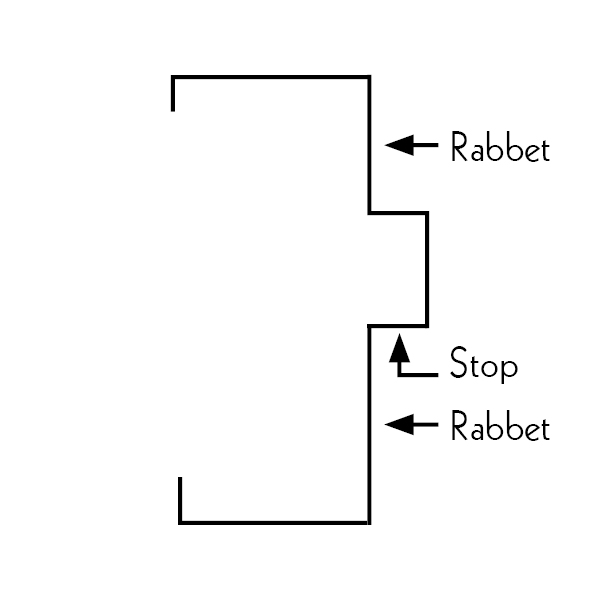

The most common door frame profile is a double rabbet, which are frames with two rabbets with a stop in between them. The rabbets can be equal or unequal.

Technical Details

| The Line’s Specifications | |

|---|---|

| Weight | About 18000kgs |

| Whole line’s dimension | About 35m x 3m x 1.5m (length x width x height) |

| Color | Main color: green |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 0.8-1.2mm |

| Coil width | According to products size |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | About 22 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 10-15m/min |

| Production Speed | about 4m/min |

| Forming rollers material | Gcr15 mould steel, with quenched treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | siemens PLC and Yaskawa Converter |

| Electric Power requirement | Main motor power: 15kw |

| Hydraulic unit motor power: 15kw | |

| Electric voltage | According to customer’s requirement |

| Main Components | |

| Decoiler (manual and automatic for options) | 1 set |

| Guiding device | 1 set |

| Leveling system motor 4kw | 1 set |

| hydraulic Punching machine with servo feeding 3kw | 1 set |

| Hydraulic Cutting system | 1 set |

| Roll Forming system motor 15kw | 1 set |

| PLC control box | 1 set |

| Hydraulic unit | 1 set |

| Run outs tables | 1 set |

No relate news.