Brazil customersend us three roofing design, that is popular

trapezoidal tile TP25-1050

trapezoidal tile TP35-1050

trapezoidal tile TP40-1050

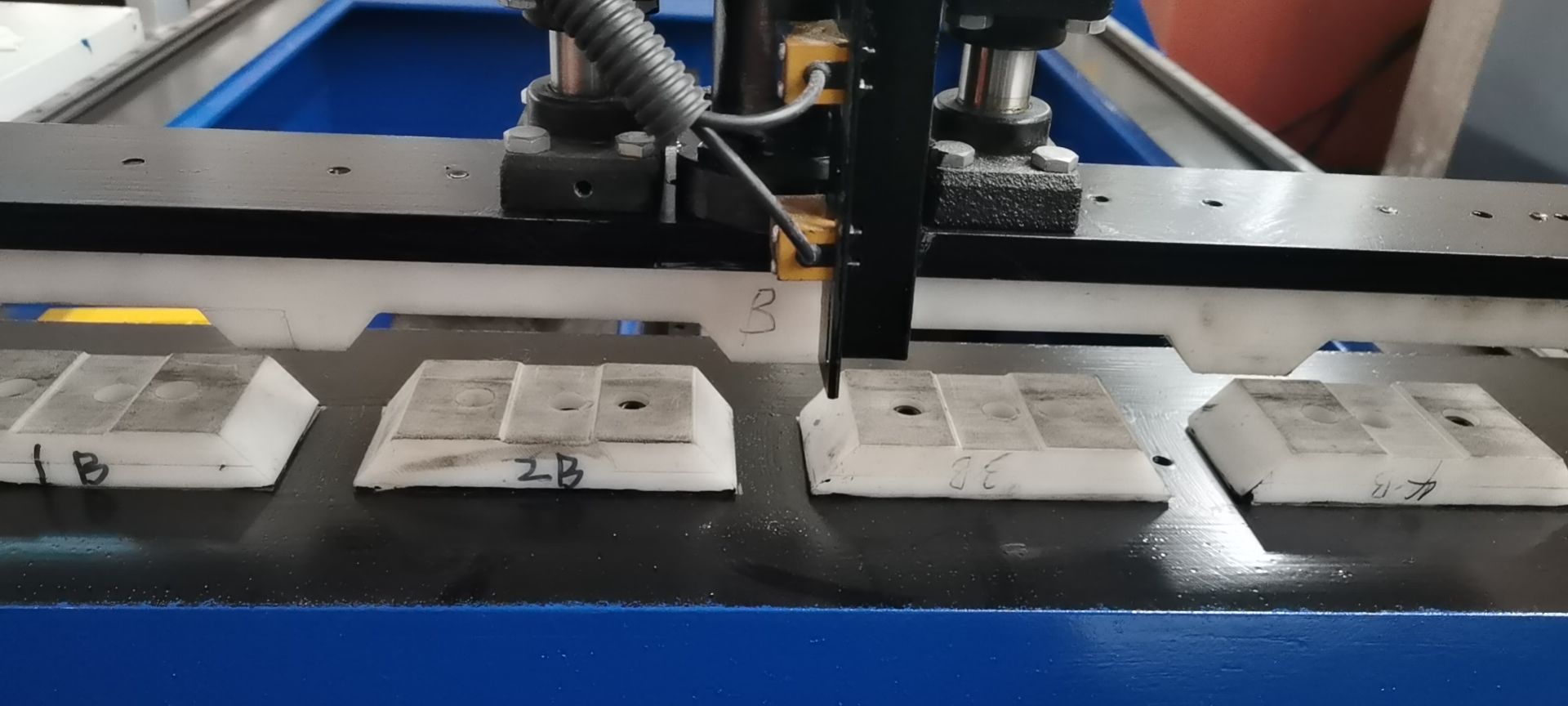

each tile 3 sheets, each length 3m, one sheet is for us to measure the design for crimping mould and test machine,

the other two sheets wait to test when machine is ready, his inspector will test on machine.

usually one crimping machine make one crimping sheet

this crimping roofing sheet machine is new design, change press arm and crimping mould for another roofing design

it is easy to change, only loose screws and tight screws.

another advantage of this crimping roofing sheet machine

machine use servo motor, which is fast to start and stop, also more accurate than usual motor.

crimping about 20 times per minute

1) Width of steel sheet: according to roof sheet profile and samples.

2) Suitable Material thickness: 0.3-0.65mm PPGI,GL and GI; Yield Strength: 235Mpa.

3) SERVO FEEDING : ABOUT 1.5kw (Depend on final design).

4) Hydraulic station power: ABOUT 5.5kw (Depend on final design).

5) Suitable power voltage: 220V60HZ/3Phase (or depend on customers requirement).

6) Crimping length: min. 25mm, max. crimping length, no limited.

7) Crimping times: about 20times /minute.

8) Bending: By hydraulic.

9) Control:SIEMENS PLC and screen, .YASKAWA inverter

10) Curving roller material: 42CR mould steel.