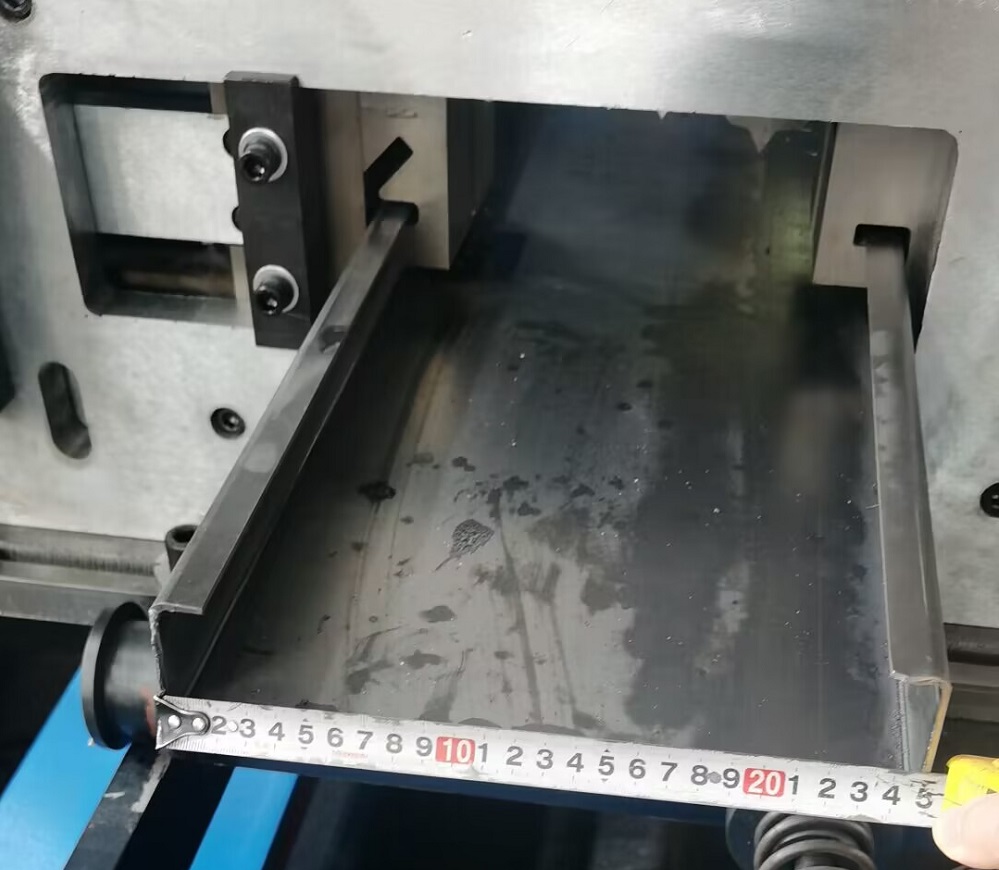

This C Purlin Forming Machine to Mexico, make size 100-300mm, material thick till 3.2mm, easy to change size, automatically work

because machine to make thickness till 3.2mm, we make main motor bigger, 18.5kw. and special treatment to shaft to guaratee their strong.

How to set up c purlin machine?

for machine can make multi size, we will ask customer what size he like when leave the factory

our technician will go if required

Suiting raw material for purlin roll former

1 ) Suitable Coil Thickness: 1.5mm -3.2 mm

2 ) Suitable Raw Materials: galvanized steel sheet

3) Yield strength of raw material: 235-345Mpa

Main parameters of purlin roll forming machine

1) Forming Speed: Max. About 15m/min. (excluding the cutting time)

2) Main Motor Power: 18,5KW (Depend on final design)

3) Hydraulic Station Power: 5.5KW (Depend on final design)

4) Control System: Mitsubishi or Siemens PLC and transducer (Japan)

5) Encoder: Nemicon (Japan)

6) Rollers’ material GR15 Steel with quench treatment

7) Shaft diameter 70mm, tooled by grinding machine for two times

to ensure the precision of final product.

8) Type of Cutting: Length-set cutting and post forming style

9) Electric Condition: 440V/3Phase/60HZ(or depend on customer)

10) Total Weight: About 11ton

Main components of purlin roll forming machine

(1) Manual decoiler 1 set(Capacity : 3 tons)

(2) Roll-Forming M/C 1 set

(3) Hydraulic Cutting 1 set

(4) Hydraulic station 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set

Note: hydraulic decoiler and pre cut device is optional with additional cost.