standard c z purlin roll forming machine make size 100-300mm C purlin and Z purlins, raw material thickness 1.5-3.0mm.

cz purlin machine is well installed and tested before delivery.

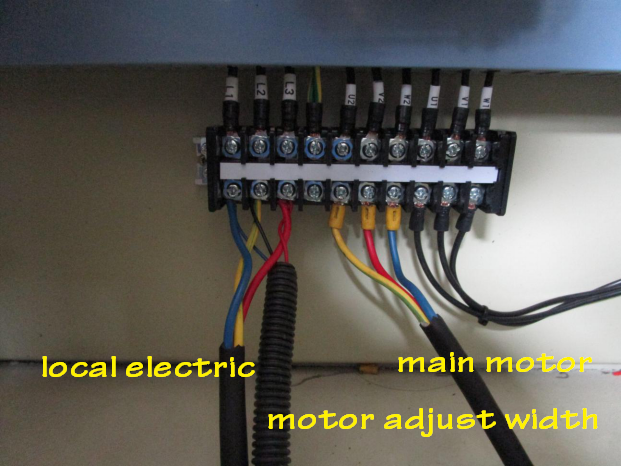

when you get machine , you only connect some wire and tube according to video. or instruction manual with pictures.

STEP 1. Please put machine body on the ground leveling first.

Release the tubing, wires and other fittings, please check if there is any spare part broken.

STEP 2. Please find these two tubings from machine, then connect them to hydraulic station.

STEP 3. Please find two Rubber bands for connecting the tubing and hydraulic station to avoid hydraulic oil`s leaking out.

STEP 5. Please add No 46. Hydraulic oil about 120L into hydraulic station.

STEP 6. There are two holes on the side of PLC. One from hydraulic station, one from cutter.

STEP 7. Please open the back door of PLC controller. Then please find wires on main machine which connected to PLC controllers. These wire will control main motor.(The main motor will work.). Connected the main wire L1,L2,L3. You may find the connected place at the back of the PLC control box.

how to program cz purlin machine?

how to change between C and Z purlin?

how to change CZ purlin size?

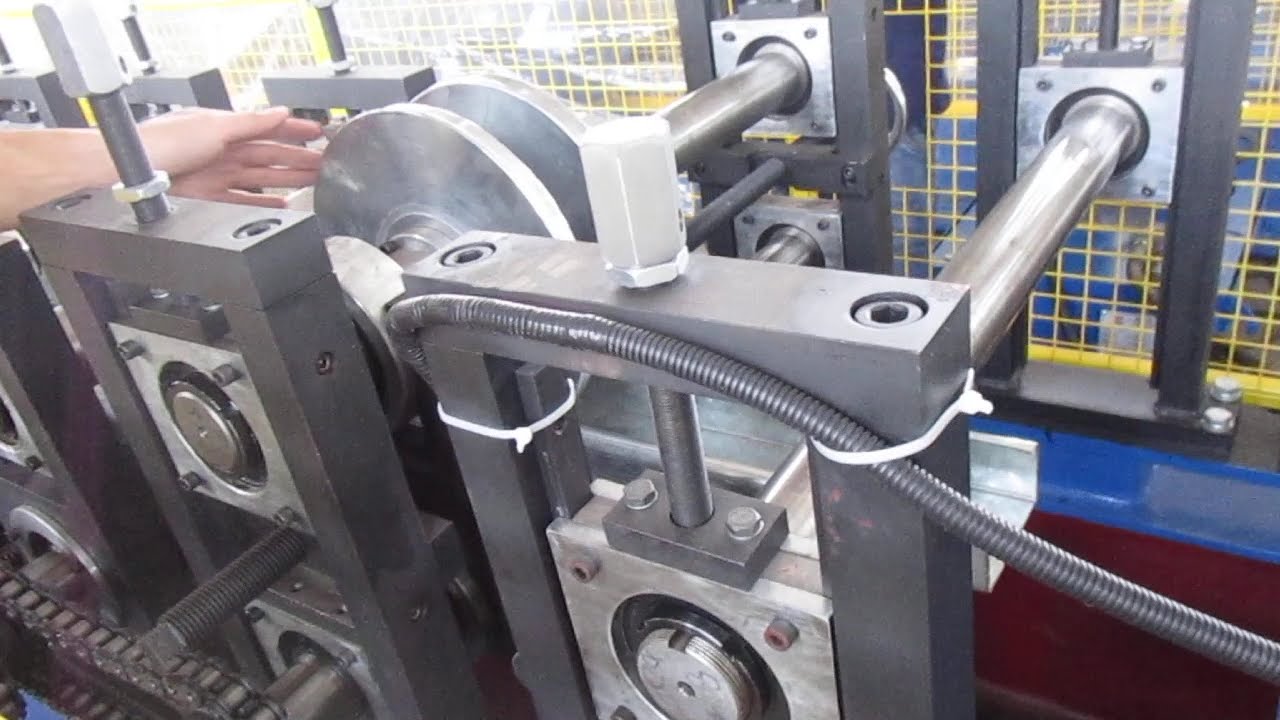

Step 1 move size from 152 to 101mm

step 2 move flange to 50mm

step 3 little adjustment and see all rollers on the same line

step 4 adjust feeding device

step 5 forming

step 6 adjust roller for rib forming

step 7 adjust cut blade according to purlin inside