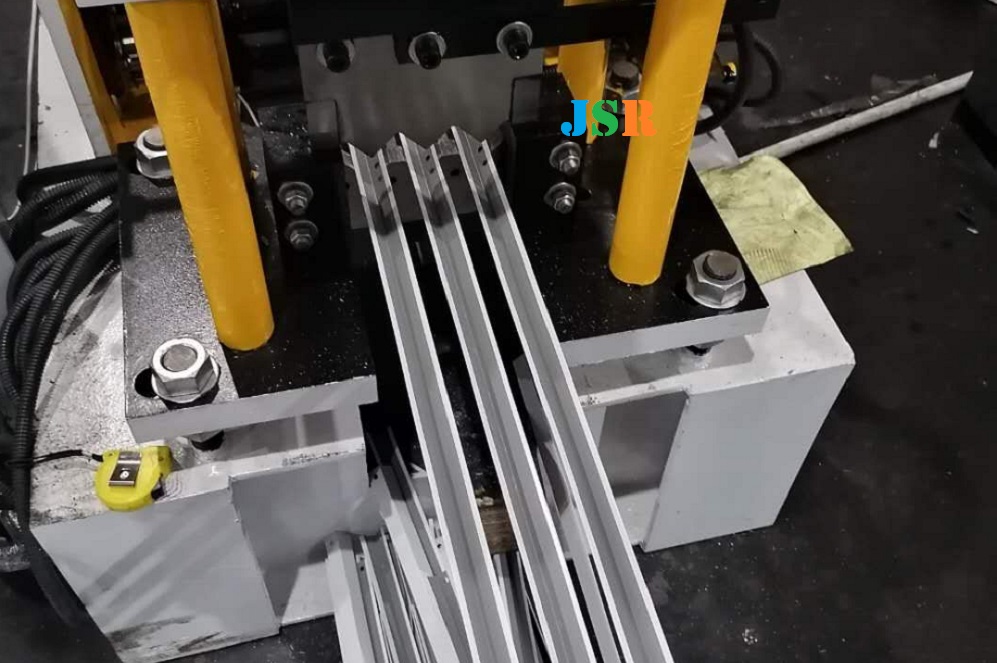

Trim roll former (multi – profiles) make two or three products at one time to improve productions.

workflow of trim lines,

decoiler- feeding – slit width-punch – forming – cut

siemens control, about 14 roller stations

trim forming machine adopt servo motor to improve working speed.

We can make roll forming for single trim, or roll former for multi profiles.

Technical Details

| Machine Specifications | |

|---|---|

| Weight | About 3500kgs |

| Size | About 8m x 1.5m x 1.5m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 0.3-0.6mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 12-14 |

| Diameter of forming rollers shafts | 60mm |

| Roll Forming Speed | about 30m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main servo motor power: 4kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |