this tube forming machine need welding device ,

process is decoiler-forming- welding-cutting

we have another type, no need welding,

process : decoiler-forming-cutting

Suiting raw material for roll former

1 ) Suitable Coil Thickness: 0.9mm -1.5 mm

2 ) Suitable Raw Materials: galvanized steel sheet

3) Yield strength of raw material: 235-345Mpa

Main parameters of roll forming machine

1) Forming Speed: Max. About 15m/min. (excluding the cutting time)

2) Main Motor Power: 11KW(Depend on final design)

3) Control System: Mitsubishi PLC and transducer (Japan)

4) Encoder: Nemicon (Japan)

5) Rollers’ material High grade No.45 forged steel, with digital-controlled procession,

plated with chrome on surface.

6) Shaft diameter 75mm, tooled by grinding machine for two times

to ensure the precision of final product.

7) Type of Cutting: Length-set cutting and post forming style

8) Electric Condition: 440V/3Phase/60HZ(or depend on customer)

9) Total Weight: About 5500 Kg

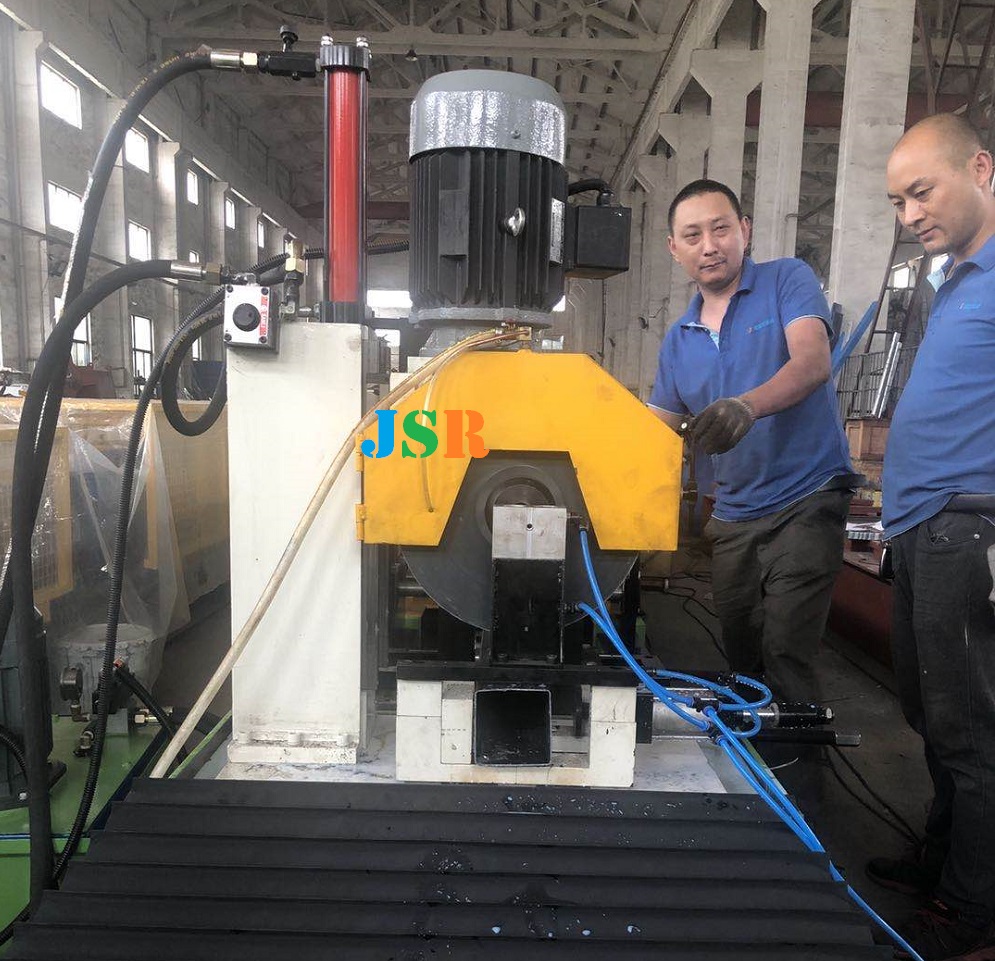

Main components of roll forming machine

(1) Manual decoiler 1 set(Capacity : 3 tons)

(2) Roll-Forming M/C 1 set

(3) Hydraulic Cutting 1 set

(4) Hydraulic station 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set